Photonics

Light-Matter Interactions

Photonics is the study of photons and their manipulation through light matter interactions. To develop the right light-reactive solutions, it is important to characterize optical properties of base materials and design configurations that yield the desired electro-optic performance.

Light is characterized by its wavelength, polarization, amplitude, phase, and propagation direction. Light-matter interaction examines the effect of the material on these properties. By tuning the material’s microscopic properties (absorption, emission, orientation, near neighbor interactions) and its constituents, you can alter the macroscopic property of a material (birefringence, complex refractive index) and its response to external stimuli (voltage, light, pressure). The key for a successful product is to develop a system that provides the proper interaction with minimal effect on the other parameters.

At AlphaMicron, we use the molecular properties of the liquid crystal and its dopants to alter individual properties of incident photons. Our focus has been on regions of the electromagnetic spectrum detected by our vision and sensors, namely, near UV 370-400nm), visible (400-700nm), and near IR (700-800nm), however we also focus on select wavelength regions in the IR.

With a fully equipped optics lab that includes pulsed and CW (continuous wave) lasers, Spectrofluorometers, FTIR, and fast detectors, we can fully characterize the electro-optical response of a system. Below are some of the example of the systems created by AlphaMicron for their clients.

Photonics – The Scientific Details

AlphaMicron has active photonics programs in a variety of applications.

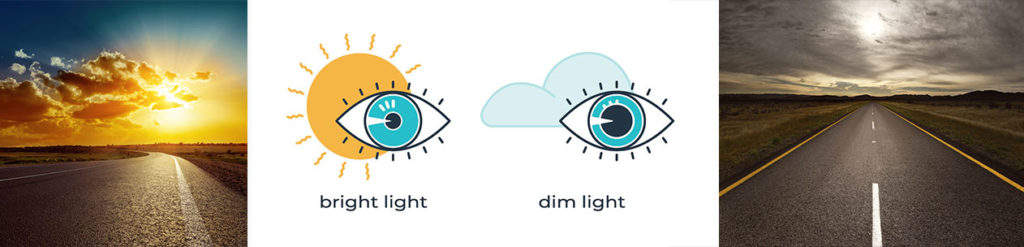

Our eyes are very sensitive to the intensity of ambient light. Traditionally we have addressed this sensitivity with wearing sunglasses.

However, with the need for mobility and the increasing dissemination of augmented and mixed reality (AR/MR) systems in wearable and automotive HUDs, it is not possible to have a static single-tint pair of sunglasses in all lighting conditions that a user experiences. Users need a technology that provides instantaneous tint-on-demand.

AlphaMicron’s e-Tint® technology is specifically designed to address this issue. Featuring:

- novel guest-host configurations,

- specialty LC-Dye formulations for exceptional contrast,

- proprietary flexible film fabrication processes,

- optimized electronic control,

- multi-color and neutral capability,

- exceptional material durability and flexibility.

AlphaMicron can create flexible functional films that can quickly (within 0.1-0.01 seconds) change their tint through application of a low voltage. This film can be laminated to a lens or glass to create an electronic tint-on-demand™ film. The operational characteristics of the film can be tuned using AlphaMicron’s dichroic dyes. Depending on the application, the device can be designed to have a fail-safe operation, i.e. switch to “clear state” in case of power failure. Alternatively, the device can be designed to switch to a tinted or black state in case the applied voltage stops.

AlphaMicron has used this technology to create the world’s first electronic switchable eyewear. This new category of protective eyewear has been field tested by the US Army and is now being sold to soldiers through Approved Protective Eyewear List (APEL). This provides the user with the ability to manually or automatically change the tint of the eyewear in 0.01 seconds- 100 times faster than a blink of an eye.

The technology is now being developed for augmented reality applications and see-through displays where the simultaneous control of ambient light vs. display light is paramount. AlphaMicron is working with both the military and private sectors to address this growing need.

SHGC is the fraction of incident sunlight transmitted through a window that can contribute to internal heat. As shown by Department of Energy [See Report by Lawrence Berkeley National Lab], to achieve a ZERO-Energy building, it is necessary to have a window that can be a source of energy gain rather than energy loss. In other words, a window with “active” SHGC capability. In addition to buildings, this feature is important in automotive applications where the car is exposed to continuous sunlight.

SHGC is the fraction of incident sunlight transmitted through a window that can contribute to internal heat. As shown by Department of Energy [See Report by Lawrence Berkeley National Lab], to achieve a ZERO-Energy building, it is necessary to have a window that can be a source of energy gain rather than energy loss. In other words, a window with “active” SHGC capability. In addition to buildings, this feature is important in automotive applications where the car is exposed to continuous sunlight.

AlphaMicron has developed an electro-optically active system that meets the requirements for SHGC control. The ASHCG system is implemented on flexible films to provide on-demand light management. The system can provide highly tinted films with high optical clarity (low haze) as well as highly tinted privacy films (high scattering). Each can be tailored for different applications.

In the automotive arena, autonomous cars are pushing the boundaries of classic design. For example, we are seeing a paradigm shift in glazing design: an open architecture for a car that will require more see-through panels (sunroof, windows). For cars, ASHCG is a necessity but a challenge given the large spectrum of sun exposure experienced by cars (think Florida summers to Minnesota winters).

AlphaMicron is working closely with a strategic partner, Dai Nippon Printing (DNP) of Japan, to develop and manufacture a solution that meets these requirements. Their joint venture, Akari LLC, commercializes ASHGC films for the next generation of architectural windows, electronically tintable sunroofs, and other glazing applications. This technology is implemented on large area films that provide the needed SHGC protection while allowing the passengers to selectively change their visibility through any of the panels. Watch the video here.

Between 2005 and 2014, more than 20,000 laser incidents were reported in US. These are events where a pilot is dazzled by a laser light during flight. The increasing number of reports of laser events by pilots underscores the urgent need for ocular protection against laser radiation.

Between 2005 and 2014, more than 20,000 laser incidents were reported in US. These are events where a pilot is dazzled by a laser light during flight. The increasing number of reports of laser events by pilots underscores the urgent need for ocular protection against laser radiation.

One obstacle to overcome in this system is to create a device that does not alter the visual perception of the pilot (colors) during takeoff and landing to ensure that the device does not interfere with the cockpit displays- which means ideally, a system is needed that is only activated in the event of a hit by a laser.

AlphaMicron scientists have been working on developing an Integrated Laser Intercept Device or i-LID™– a liquid crystal-based switchable photonic band gap system engineered for aircrew eye protection against intense laser radiation. The liquid crystal cells can be designed to either protect against an individual laser wavelength or collectively against all wavelengths without having a predetermined tint color in the eyewear, which can conflict with cockpit displays.

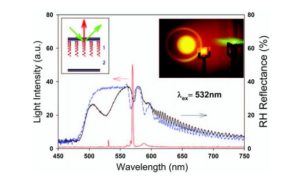

Photonic bandgap materials have become of significant importance in photonic and optical applications. One of the leading demonstrations has been photonic bandgap lasing in cholesteric liquid crystals (CLCs). AlphaMicron scientists, working alongside scientists from Kent State University’s Liquid Crystal Institute, are pioneers in this field and have demonstrated lasing in a number of liquid crystal systems including pure liquid crystals, dye-doped liquid crystals, polymeric liquid crystals, elastomeric liquid crystals, and most recently in chirped chiral systems where continuous wave or CW lasing was observed.

Photonic bandgap materials have become of significant importance in photonic and optical applications. One of the leading demonstrations has been photonic bandgap lasing in cholesteric liquid crystals (CLCs). AlphaMicron scientists, working alongside scientists from Kent State University’s Liquid Crystal Institute, are pioneers in this field and have demonstrated lasing in a number of liquid crystal systems including pure liquid crystals, dye-doped liquid crystals, polymeric liquid crystals, elastomeric liquid crystals, and most recently in chirped chiral systems where continuous wave or CW lasing was observed.

Our scientists were also the first to observe mirrorless lasing in three- dimensional photonic crystals in blue phase cholesteric liquid crystals. Paper: Cao & Munoz, Lasing in a three-dimensional photonic crystal of the liquid crystal blue phase II, Nature Materials 1, 111–113 (2002).