Design & Prototyping

Products That Revolutionize Industries

Patented and award-winning approaches to creating light-reactive products

AlphaMicron’s work with consumer product design spans from meeting the demands of world-class athletes to an area where the stakes are the highest: developing products for the military. Our ability to successfully produce highly responsive, effective light-reaction solutions that meet the strict requirements and life-or-death needs of our clients in both of these sectors led us to be the undisputed leader in the field.

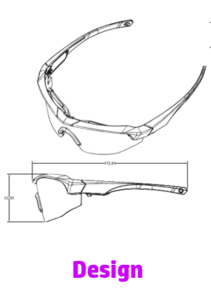

Today, our CTRL products are part of the prestigious Army’s Authorized Protective Eyewear List (APEL) as the only spectacle and goggle with electronic Tint-on-Demand™ capability that meets the highest ballistic requirements as outlined in MIL-SPEC-32-432A. This eyewear gives warfighters the unique ability to transition between sunny outside conditions and dark interiors without the need to remove their tinted safety gear.

AlphaMicron works with organizations all over the world to push the boundaries of what’s possible with wearable consumer products. Our in-depth knowledge and expertise allows us to customize and optimize all aspects of product design. Together with industrial designers, our engineering team helps incorporate the technology (liquid crystal device and electronics) into various form factors and assists in system integration.

To date, we have had development projects in several industries including military, law-enforcement and sports eyewear; automotive windows, sunroofs and mirrors; see-through and near-eye displays; professional cinematography cameras; augmented reality and virtual reality devices; architectural applications; and most recently NASA’s space suit visors. We are also responsible for the high-performance CTRL® brand of electronic eyewear, the Uvex variotronic ski goggle, and the Akari motorcycle visor inserts, all featuring e-Tint® technology.

All products are designed and developed by scientists and engineers in-house at our state-of-the-art facility in Kent, Ohio and meet the needs of the most demanding users.

Our motorcycle visor insert was endorsed by nine-time motorcycle road racing world champion Valentino Rossi.

Our Design & Prototyping services include:

AlphaMicron has pioneered flexible-substrate LC systems by making the world’s first commercially available electronically tintable eyewear using liquid crystals in plastic films. Our flexible substrates are compatible with a variety of liquid crystal technologies including guest-host, polarizer based, reflective based and scattering as well as devices with three states.

Traditionally, LCD’s and light management devices using liquid crystals were made with glass substrates. The problem with glass is that it cannot be used for high performance eyewear, visors or goggles because (a) it is not impact resistant, (b) it is heavy, and (c) it is rigid and very difficult to conform. The obvious solution is to use plastic substrates. However, the challenge with using flexible plastic substrates for LC devices is a myriad of material-related problems: from the fact that transparent conductors, polyimides, glues and spacers need to be compatible with low temperature processing; to process-related issues such as the maintenance of a constant cell gap and the handling of thin, flexible substrates.

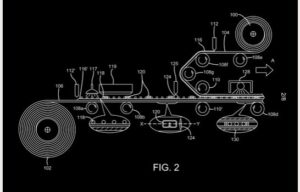

AlphaMicron’s material scientists and engineers have solved these problems and have created various devices and prototypes using a variety of LC systems implemented on flexible substrate that does not use any polymers. With a full in-house manufacturing line, AlphaMicron prototypes and manufactures liquid crystal devices for several industries. In addition to traditional methods, we have developed a unique roll-to-roll manufacturing line for fast efficient production. Not only can AlphaMicron fine-tune its technology/manufacturing line to create prototype products, but this unique production technology is being used by large-film manufacturing companies to scale-up production capabilities. [Link to DNP partnership] .

Our comprehensive, ISO 9001:2015 compliant in-house manufacturing line and over 10,000 square ft of clean rooms allow us to design and create products in ideal conditions.

Our comprehensive, ISO 9001:2015 compliant in-house manufacturing line and over 10,000 square ft of clean rooms allow us to design and create products in ideal conditions.

It is important to ensure that any design can be seamlessly integrated into a device. There are a number of parameters that have to be considered for a successful implementation and commercialization of a technology. AlphaMicron uses 3D printing and in-house fabrication to test the prototyped items for form-fit-function as well as to examine the scalability of the product.

Driver electronics including Bluetooth-enabled options, giving users complete control over optical performance

To drive the various LC devices carrying different modes of liquid crystal, customized driver electronics with different functionalities have to be designed.

AlphaMicron has a full electronics lab that designs, tests and prototypes electronics for driving the liquid crystal devices that are prototyped and manufactured by AlphaMicron. The hardware provides a unique proprietary driving scheme which is tuned to the performance of our materials and systems, including e-Tint®. The electronics, which can be Bluetooth enabled, give the user complete control over the optical performance of the device at the touch of a button. The electronics are designed to minimize power consumption and maximize the longevity of the device.

For remote control and device management.

In addition to electronic hardware, AlphaMicron’s has developed iOS and Android compatible software that can be used to allow the user to manage the performance of an electronically driven LC device at a touch of a button, remotely through Bluetooth, or via an external controller directly from their phone. The software is programmed for each application.

We are currently working on allowing voice activation to drive and control various LC devices such as one-way mirror films for school security, windows with multi-color capability and sunroofs.

Our proprietary processing techniques allow us to make conformal LC films with complex curvatures.

Our proprietary processing techniques allow us to make conformal LC films with complex curvatures.

AlphaMicron pioneered flexible liquid crystal devices for curved conformal applications including Air Force visors, sunroofs, and automotive cockpit displays. We invented a new process for shaping and molding non-pixelated flexible liquid crystal cells (containing non-polymerized LC) to retain single or double curvature and function while containing a fluid electro-optically active material; we hold several worldwide device and process patents in this area.

This processing has enabled the world’s first ever switchable LC devices on curved plastic.

In recognition of this pioneering work, AlphaMicron, together with Boeing, are the only companies who were awarded a Next-Generation Space Suit NASA program to design and implement a new ExtraVehicular Visor Assembly (EVVA) to carry out its heritage mission of protecting the astronauts’ eyes from harmful radiation while also incorporating new designs that maximize overhead visibility and incorporate new technology.

Designs that minimize power consumption and maximize device longevity.

Designs that minimize power consumption and maximize device longevity.

As a pioneer, AlphaMicron engages and works with industry leaders to create a designed solution that meets the requirements associated with each project.

Since all materials, system parameters, and electronics for each prototype and device are designed and developed in-house at AlphaMicron, the team has developed the requisite in-depth knowledge and expertise needed to optimize all aspects of product design. Together with industrial designers, the engineering team at AlphaMicron helps incorporate the technology (liquid crystal device and electronics) into various form factors and assists in device integration.

- Voice-activation,

- Customized AR/VR devices,

- Switchable one-way mirror films for school security

We have continuously won awards for our designs and always look forward to the next challenge.

Some samples of current Prototypes:

One-Way Mirror – school security controlled with Alexa

Multi-colored window controlled with Alexa

Switchable sunroof controlled with Alexa